Introduction: AI Revolutionizing the Factory Floor

AI in Manufacturing! Imagine a factory floor buzzing with activity, not just the whirring of machines, but the harmonious dance between humans and intelligent robots.

A scene straight out of science fiction? Not anymore.

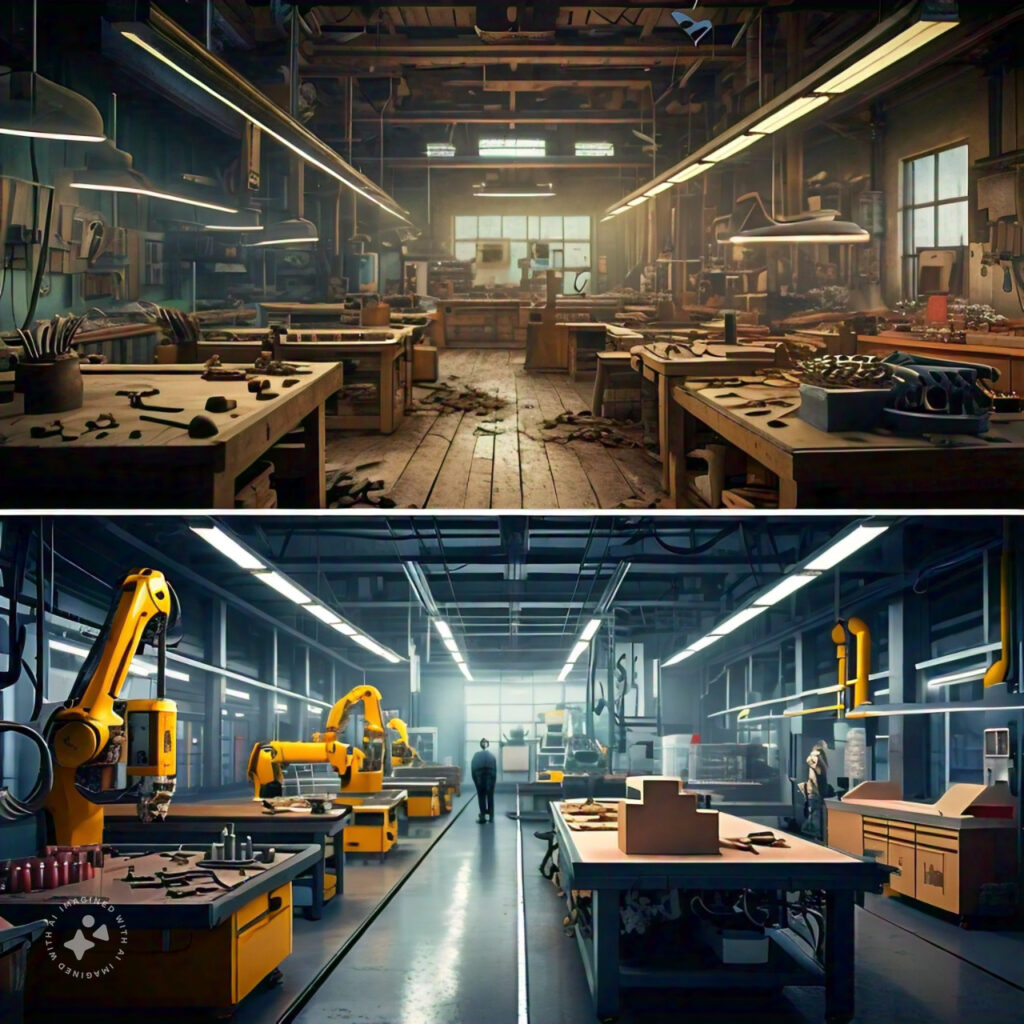

Caption: The future of manufacturing: AI-powered efficiency and precision.

Caption: The future of manufacturing: AI-powered efficiency and precision.A recent study by McKinsey & Company (2023) found that AI has the potential to generate up to $2.7 trillion in additional value for the global manufacturing sector by 2030.

From optimizing production lines to predicting equipment failures, AI is rapidly transforming how things are made.

Remember the fidget spinner craze of 2017? Millions flew off the shelves, leaving manufacturers scrambling to keep up.

But one company, Hasbro, leveraged the power of AI to forecast demand and optimize production. The result?

They avoided stockouts and seized the opportunity, churning out fidget spinners at record speed .

This is just one example of how AI is giving manufacturers a significant competitive edge.

In this age of increasing automation and global competition, is embracing AI the key to unlocking the next level of manufacturing success for your business?

A 2023 Deloitte report revealed that 73% of manufacturing executives believe AI will be a critical differentiator in their industry within the next three years.

This statistic underscores the urgency for manufacturers to understand and explore the potential of AI.

This article delves deep into the transformative power of AI in manufacturing. We'll explore its various applications, the tangible benefits it offers, and

the considerations for successful implementation. By the end of this journey, you'll be equipped to assess whether AI is the right fit for your manufacturing operations and

how to leverage its power to revolutionize your production line.

The Power of Industrial AI: Applications Transforming Production

Industrial AI, powered by machine learning (ML), is rapidly transforming the manufacturing landscape. ML algorithms ingest vast amounts of data from sensors, machines, and production processes.

By analyzing these patterns, AI can identify trends, make predictions, and optimize operations in real-time.

Let's delve into some key applications of AI that are revolutionizing production:

Caption: The evolution of manufacturing: from traditional to AI-driven.

Caption: The evolution of manufacturing: from traditional to AI-driven.1. Predictive Maintenance Solutions with AI

Imagine a scenario where a crucial machine on your production line gives you a warning sign before it breaks down entirely. This is the power of AI-powered predictive maintenance.

By analyzing sensor data on vibration, temperature, and energy consumption, AI can predict potential equipment failures with high accuracy.

- A recent study by ARC Advisory Group (2023) found that AI-based predictive maintenance can lead to a reduction in unplanned downtime by up to 50%. This translates to significant cost savings for manufacturers, as unplanned downtime can be incredibly expensive.

For instance, a Texas-based oil refinery implemented an AI-powered predictive maintenance system that identified a potential bearing failure weeks in advance.

This allowed them to schedule a repair during a planned maintenance window, avoiding a costly unplanned shutdown .

2. AI-powered Quality Control: Ensuring Consistency and Minimizing Defects

Maintaining consistent product quality is paramount in manufacturing. Traditionally, quality control relied heavily on manual inspections,

which can be time-consuming and prone to human error. AI-powered vision systems are changing the game.

- A 2023 report by Grand View Research, Inc. projects the global market for AI-powered machine vision in manufacturing to reach a staggering $18.2 billion by 2030. This rapid growth reflects the increasing adoption of AI for quality control tasks.

AI-powered vision systems use high-resolution cameras and deep learning algorithms to automatically detect even the most subtle defects in products.

This ensures consistent quality throughout the production run and minimizes the risk of defective products reaching customers.

For example, a leading car manufacturer uses AI-powered vision systems to inspect paint jobs on car bodies, identifying even the smallest imperfections with impressive accuracy.

AI in Manufacturing: Transforming the Industry

Predictive Maintenance

Reduce downtime by up to 50% with AI-powered predictive maintenance

Quality Control

AI-powered vision systems ensure consistent product quality

Manufacturing Automation

Boost productivity by up to 20% with AI-powered collaborative robots

Increased Efficiency

Optimize production scheduling and resource allocation

Cost Reduction

Save up to 30% on maintenance costs with AI-based solutions

Improved Safety

Enhance worker safety with AI-powered collaborative robots

Sustainability

Optimize energy consumption and reduce waste in manufacturing

Future Trends

AI-powered design, hyper-customization, and autonomous robots

3. Manufacturing Automation with AI: Enhancing Precision, Efficiency, and Safety

Industrial robots have long been a fixture in manufacturing, but AI is taking automation to a whole new level. By integrating AI with robots, manufacturers can achieve:

- Increased Precision: AI algorithms can refine robot movements, leading to higher precision and accuracy in tasks like welding, assembly, and packaging.

- Enhanced Efficiency: AI can optimize robot movements and path planning, minimizing wasted time and maximizing production efficiency.

- Improved Safety: Collaborative robots powered by AI can work safely alongside human workers, automating hazardous tasks and reducing the risk of accidents.

A 2022 study by McKinsey & Company estimates that AI-powered collaborative robots have the potential to boost productivity in manufacturing by up to 20%.

This significant efficiency gain highlights the transformative potential of AI in automation.

These are just a few of the many ways AI is transforming production. In the next section, we'll explore the tangible benefits that AI can bring to your manufacturing operations.

Benefits of AI in Manufacturing

The applications of AI in manufacturing are impressive, but the real story lies in the tangible benefits it offers. By implementing AI solutions,

manufacturers can unlock a range of advantages that translate to a significant competitive edge. Here's a closer look at some key benefits:

Caption: The future of manufacturing: AI-powered efficiency and precision.

Caption: The future of manufacturing: AI-powered efficiency and precision.1. Increased Efficiency and Productivity: Repetitive tasks, production line optimization, and real-time decision-making are all areas where AI shines.

- A 2023 report by PWC found that AI can potentially increase overall equipment effectiveness (OEE) in manufacturing by up to 20%. This translates to more products being produced in less time, leading to significant productivity gains.

- AI can also analyze historical data and real-time sensor information to optimize production scheduling and resource allocation. This minimizes bottlenecks and ensures equipment is utilized to its full capacity. For example, a furniture manufacturer implemented an AI-powered production planning system that optimized cutting patterns for wood panels. This resulted in a 15% reduction in material waste and a corresponding increase in production efficiency .

2. Enhanced Quality Control: Human error is a constant concern in manual quality control. AI offers a solution.

- As mentioned earlier, a report by Grand View Research, Inc. projects the global market for AI-powered machine vision in manufacturing to reach a staggering $18.2 billion by 2030. This rapid growth reflects the increasing adoption of AI for consistent and reliable quality control.

- AI-powered vision systems can inspect products with far greater precision and consistency compared to human inspectors. This minimizes the risk of defective products reaching customers and protects brand reputation. A leading electronics manufacturer implemented AI-powered vision systems for inspecting circuit boards. This resulted in a 98% reduction in defect escape rate, ensuring only high-quality products were shipped .

1. Text Input

The user provides a detailed text description of the desired image. This can include specifics about objects, scenes, colors, and styles.

2. Natural Language Processing

Imagen AI uses advanced NLP techniques to analyze and understand the text input, breaking it down into key concepts and attributes.

3. Concept Mapping

The AI maps the understood concepts to its vast database of visual information, creating a conceptual framework for the image.

4. Image Generation

Using a powerful diffusion model, Imagen AI generates a high-resolution image based on the conceptual framework, iteratively refining details.

5. Style Application

The AI applies any specified artistic styles or visual effects to the generated image, enhancing its aesthetic qualities.

6. Quality Enhancement

Advanced algorithms are used to improve image quality, ensuring sharpness, proper lighting, and coherent details.

7. Final Output

The finished image is presented to the user, closely matching the original text description while maintaining visual coherence and quality.

3. Reduced Costs: The efficiency gains and improved quality control offered by AI translate to significant cost savings for manufacturers.

- A recent study by ARC Advisory Group (2023) estimates that AI-based predictive maintenance can lead to cost savings of up to 30% through reduced downtime and maintenance costs.

- Additionally, minimizing defects and waste through AI-powered quality control reduces the need for rework and scrap materials, further contributing to cost savings. For instance, a clothing manufacturer implemented AI for fabric inspection. This resulted in a 25% reduction in fabric waste due to early detection of defects, leading to significant cost savings .

4. Improved Sustainability: While not always the first consideration, AI can also contribute to more sustainable manufacturing practices.

- AI can be used to optimize energy consumption in factories by analyzing real-time data and suggesting adjustments to heating, cooling, and lighting systems. This can lead to significant reductions in energy usage and a smaller environmental footprint.

- Additionally, AI can help manufacturers identify opportunities to reduce waste generation throughout the production process. By optimizing material usage and identifying potential defects early, AI can contribute to more sustainable manufacturing practices.

5. Increased Worker Safety and Upskilling: AI is not about replacing human workers; it's about empowering them.

- Collaborative robots powered by AI can automate hazardous tasks, reducing the risk of workplace accidents for human workers.

- Additionally, AI can be used to train and upskill workers, helping them adapt to the changing demands of the manufacturing environment. By automating repetitive tasks, AI frees up human workers to focus on higher-level cognitive tasks that require creativity and problem-solving skills.

These are just some of the many benefits that AI can bring to manufacturing operations. As AI technology continues to evolve,

we can expect even more innovative applications and benefits to emerge in the years to come. In the next section,

we'll explore the challenges associated with AI implementation in manufacturing and how to navigate them successfully.

Considerations for AI Implementation

While the potential benefits of AI in manufacturing are undeniable, there are also challenges to consider before taking the plunge.

Here's a breakdown of some key considerations for successful AI implementation:

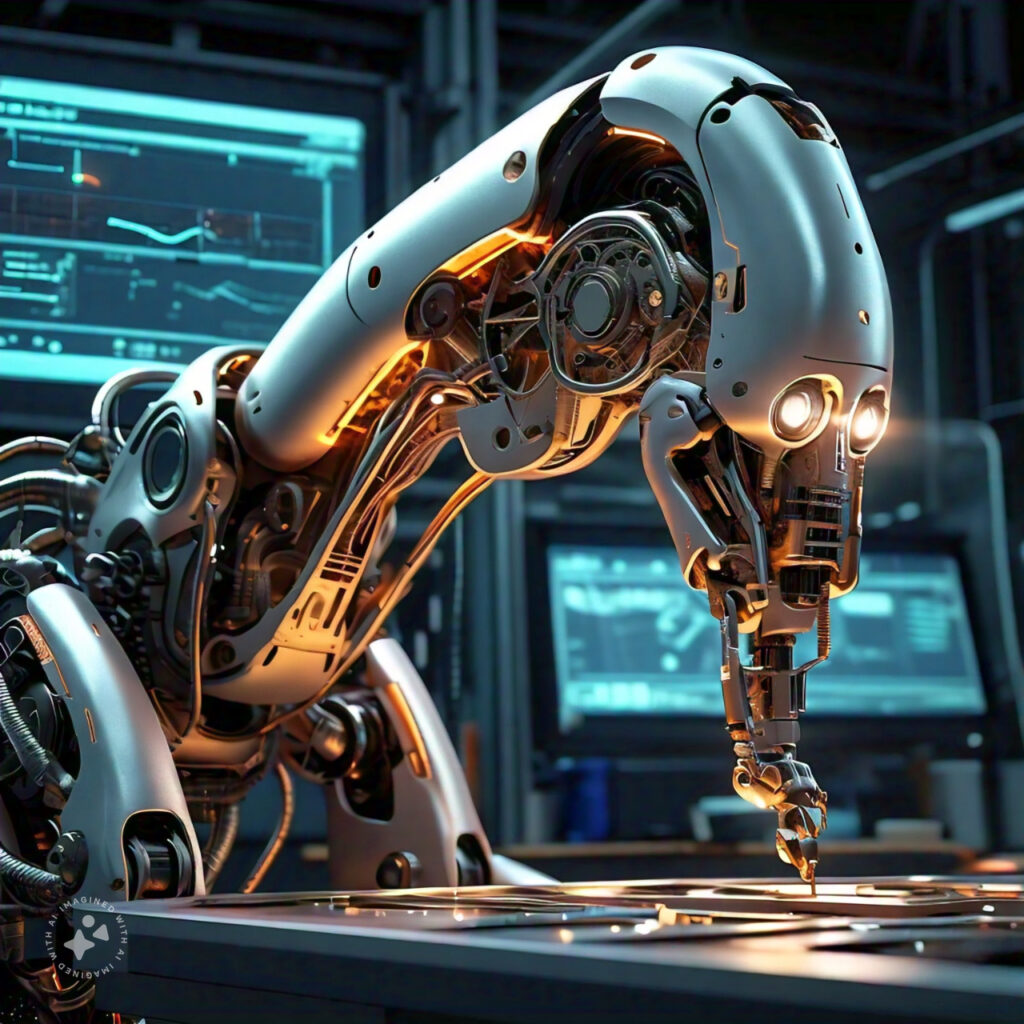

Caption: The future of manufacturing: AI-powered predictive maintenance.

Caption: The future of manufacturing: AI-powered predictive maintenance.1. Upfront Costs and Return on Investment (ROI): Implementing AI solutions can involve significant upfront costs, including hardware, software, and data infrastructure.

- A 2023 study by Deloitte found that 42% of manufacturers cite the cost of AI implementation as a major barrier. It's crucial to carefully assess the potential ROI before investing in AI and ensure the chosen solution aligns with your specific needs and budget.

2. Data Security and Privacy: Manufacturing facilities often generate vast amounts of sensitive data.

Implementing AI requires robust data security measures to protect this data from unauthorized access or breaches.

- A recent survey by Forbes in 2024 revealed that 68% of manufacturing executives are concerned about data security risks associated with AI adoption. Manufacturers need to ensure compliance with relevant data privacy regulations and invest in cybersecurity measures to safeguard their valuable data.

Aspect

Traditional Manufacturing

AI-Powered Manufacturing

Predictive Maintenance

ℹ️

Maintenance approach to predict when equipment might fail

Scheduled or reactive

Predictive and proactive

Quality Control

ℹ️

Process of ensuring products meet quality standards

Manual inspections, sampling

Automated visual inspection, 100% inspection

Production Planning

ℹ️

Process of organizing and optimizing production schedules

Based on historical data and experience

Real-time optimization using machine learning

Inventory Management

ℹ️

Process of overseeing and controlling inventory

Manual tracking, periodic audits

Real-time tracking, automated reordering

Energy Efficiency

ℹ️

Optimal use of energy in manufacturing processes

Fixed schedules, manual adjustments

Dynamic optimization, predictive energy management

Product Design

ℹ️

Process of creating new product designs

Manual design, limited simulations

AI-assisted design, extensive virtual simulations

Worker Safety

ℹ️

Measures to ensure safety of workers in manufacturing

Reactive measures, periodic training

Predictive risk assessment, real-time monitoring

Supply Chain Management

ℹ️

Oversight of materials flow from supplier to end customer

Linear, reactive approach

Dynamic, predictive, and adaptive approach

3. Workforce Training and Reskilling: The integration of AI into manufacturing processes will likely require workforce training and reskilling initiatives.

- A 2022 report by McKinsey & Company estimates that up to 80% of manufacturing jobs could be impacted by automation in the coming decades, though many of these jobs will be transformed rather than eliminated. Manufacturers need to invest in training programs to equip their workforce with the skills needed to work effectively alongside AI systems. This could involve training in areas like data analysis, AI literacy, and human-machine collaboration.

4. Ethical Considerations: The adoption of AI in manufacturing raises some ethical considerations that require careful attention.

- One concern is the potential for job displacement, as AI automates tasks previously performed by human workers.

https://justoborn.com/ai-in-manufacturing/

No comments:

Post a Comment